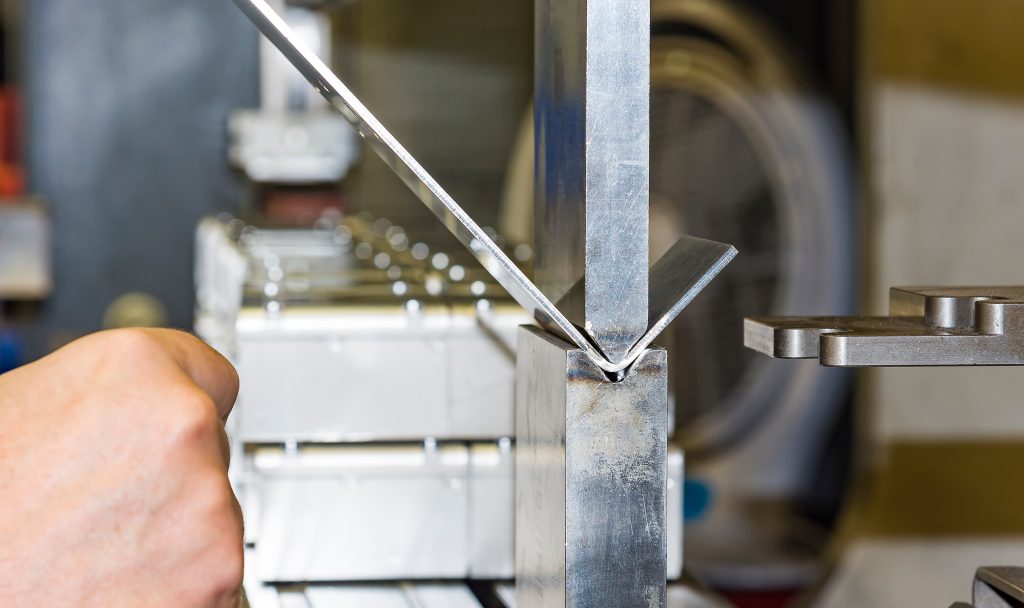

The future of metal bending: exploring new technologies and trends

The medical industry plays a crucial role in improving the quality of life and saving lives worldwide. Within this sector, metal bending plays a significant role in the production of precision components and parts used in various medical devices. In this article, we will discuss the importance of metal bending in the medical industry, new technologies in this process, and trends in component and part design.

The significance of metal bending in the medical industry

Precision and quality

In the medical industry, precision and quality are paramount. Components and parts used in medical devices must be accurate and reliable. Metal bending enables the creation of precise shapes and dimensions, which are essential in healthcare.

Functionality and ergonomics

Medical devices often contain complex components that must operate smoothly and be ergonomic in use. Metal bending allows for the design of parts that meet these criteria.

Durability and hygiene

Medical components must be durable and easy to clean and disinfect. Metal parts subjected to bending are resistant to wear and easy to maintain.

New technologies in metal bending services

CNC (Computer Numerical Control)

CNC technology allows for the control of the metal bending process using a computer, increasing precision and repeatability. This enables the creation of more complex shapes and reduces the risk of errors.

Automation

Automating the metal bending process accelerates production and minimizes the risk of human errors. Industrial robots are increasingly used in this process.

Advanced materials

Modern technologies allow for the bending of advanced materials such as titanium and metal alloys. These materials are increasingly used in the medical industry due to their durability and biocompatibility.

Trends in component and part design

Minimalism and weight reduction

A trend in designing medical components is the pursuit of minimalism and weight reduction, aiming to increase patient mobility and comfort while reducing the burden on medical staff.

Modularity

Component modularity facilitates easier maintenance and repair of medical devices. It also enhances flexibility in adapting devices to various applications.

Innovative shapes

Advanced metal bending technologies allow for the creation of more innovative shapes, potentially improving the functionality and aesthetics of medical devices.

Opportunities of new metal bending technologies

Personalization

Advanced metal bending technologies enable the personalization of medical components, leading to better alignment with individual patient needs.

Production efficiency

Automation and CNC technology enhance production efficiency, potentially reducing costs and enabling faster access to new medical devices.

Safety

Modern metal materials are more resistant to corrosion and damage, contributing to the longer lifespan of medical devices and increased patient safety.

Metal bending plays a crucial role in the medical industry, enabling the production of precise and reliable components and parts. New technologies and trends in component design allow for innovative solutions that enhance healthcare quality and patient comfort. Metal bending services are a significant part of manufacturing in this industry, supporting the development of modern medical devices.